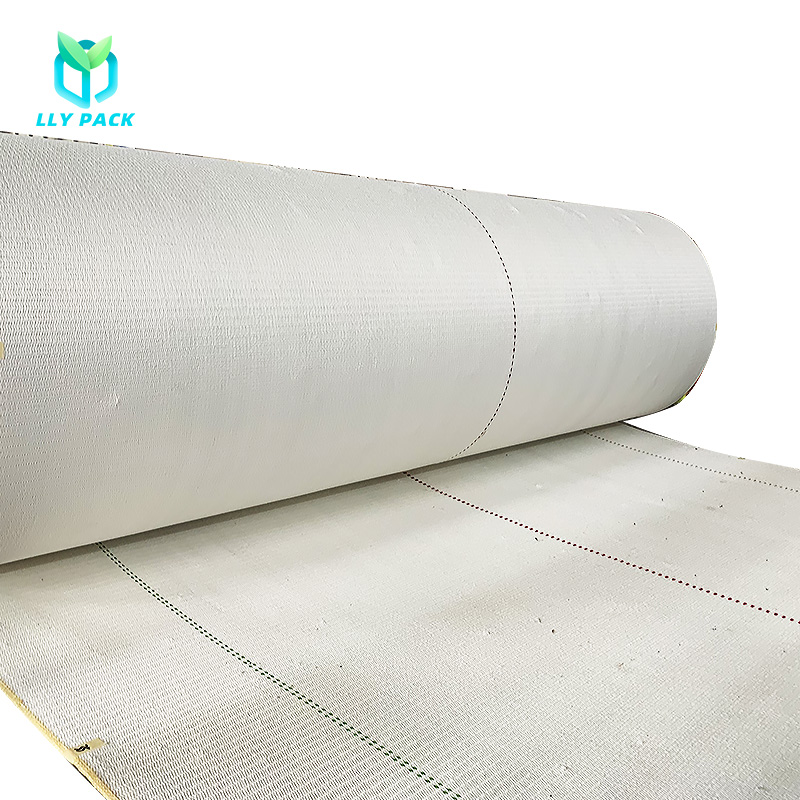

Corrugated board conveyor belt is undoubtedly one of the most important parts of the corrugated board production line. Its quality has a decisive influence on the quality of corrugated board, and has always been a concern of cartons and tile manufacturers. From the structural point of view, there are two kinds of transportation used by the corrugated board production line: one is a cotton belt, which is made of multi-layered cotton yarn, chemical fiber blended, and woven by a weaving machine. It has a large weight per unit area, uneven surface, The characteristics of large friction coefficient; the other is acupuncture belt, which is based on polyester fiber, rayon as the basic raw material, processed by multiple processes of acupuncture machine, with a smooth surface, uniform thickness, no indentation and many other The advantages are increasingly favored by the majority of users.

Innovative structure The traditional acupuncture tape structure has three layers: the surface layer, the middle layer and the bottom layer. The surface layer and the bottom layer are acupuncture flocking structure, and the middle layer is a warp roving and flocking structure. The structure itself is loose, and its unit area has low self-weight. When it is subjected to strong tension and speeds up, it not only exerts pressure, but also has very limited carrying capacity to the cardboard, and it is easy to run away. It has a high elongation rate. After several months of use, it has to re-splice steel buckles, which takes time and effort, and affects production. This is also why the acupuncture belt has been difficult to increase its share in the market for many years. Ai Ai started from the structure and successfully eliminated the above defects. Its specific approach is to use a unique production process, weaving seven layers of special PET fiber as the material in the acupuncture belt weaving layer, so that its structure is strong, the unit area of self-weight up to 5.8kg/m2, and uniform thickness. As PET fiber is a material with high temperature resistance and toughness, it greatly enhances the adaptability of acupuncture belts to high temperature, high humidity, high pressure, high tensile force and high-speed operating environment. The anti-expansion heat treatment setting method adopted by us in the production process completely solves the problem of large extension amount. The results show that when the working tension is 12 N/mm, the warping rate is only 0.3%. Generally speaking, after the corrugated board conveyor belt runs in the special environment of the tile line for a period of time, due to the continuous action of high tensile force and high pressure, the thickness of the corrugated board conveyor belt will have a certain degree of thinning; from the perspective of the cotton belt, the warp and weft yarns The characteristics of the weaving structure and the different pressures on the surface of the tape often result in smaller thicknesses at both edges of the tape. As a result, the effective width of the corrugated paperboard becomes smaller, the reject rate increases, and the cost is wasted. Ai Acupuncture Tape contains pressure-resistant, wear-resistant materials to keep its thickness stable.

Superior air permeability Breathability is the most important technical indicator of the corrugated board conveyor belt. The technical index of corrugated board corresponding to it is the moisture content. In other words, the moisture content of the corrugated board is dried through the conveyor belt. The work flow is that the conveyor belt applies pressure to the board and sticks it on the surface of the heating board, absorbs heat to evaporate water vapor, and water vapor is absorbed by the conveyor belt. And distributed in the run. Therefore, there is a very high requirement for the moisture absorption and breathability of the conveyor belt. Air permeability is too large, it will inevitably cause the paperboard to be too dry and easy to break. Poor air permeability will lead to high moisture content in the paperboard, reduced strength, warpage, and even affect the smoothness of subsequent cutting, indentation and other processes. In the production process, Ai Ai Company can control the through hole rate, the hole diameter, and the uniform distribution of the holes in a timely and effective manner with first-class production equipment, so that it has a proper amount of uniform moisture absorption and rapid emission capability. From the point of view of use, the moisture content of the corrugated board can fully reach 11±3% of the national standard, and the adhesive strength of the board is also greatly improved.

Surface Leveling and Wear We know that high-quality corrugated paperboards are characterized by high corrugation, high tensile strength, surface finish, and no indentation. These characteristics are largely achieved by the transport of the hot plate section and the cooling section. Ai Acupuncture has unique polyester fiber layer and cotton layer structure patterns and specially treated fiber materials on the contact surface, showing good elasticity, toughness and wear resistance in practical applications. It can distribute the pressure from the gravity roller to the cardboard evenly and moderately, and at the same time maintain sufficient friction and adhesion, and easily and smoothly carry the cardboard running. Especially valuable is that there is no indentation on the cardboard and the surface quality of the corrugated cardboard is improved. . This is the advantage that traditional acupuncture belts and cotton belts cannot match. Because the traditional acupuncture strips have been chemically hardened, they actually lose their original elasticity; while cotton weaves with thick-lined warp and weft woven structures, it is difficult to eliminate the surface roughness. These characteristics are often caused by the phenomenon of distorted corrugation peaks and indentation on the surface of the paperboard in an operating environment where the vehicle speed and pressure are constantly changing.

In fact, the dark joint will reduce the tensile strength of the joint area, which makes it unable to withstand long-term strong pull and crack. Ai Acupuncture Strip adopts American Clipper ear steel buckle closed type joint. It is cut into two layers at the joint area from 3mm below the strip surface, and the steel buckle is hit at the lower layer. These processes are completed by the layering machine and the steel buckle machine. The deviation caused by the joint of the artificial tool is avoided. The steel buckle is completely covered by the upper layer so that it can maintain the original moisture absorption, elasticity, toughness and wear resistance in contact with the cardboard, and completely avoids the periodic indentation of the cardboard due to the protrusion of the steel buckle.

The results show that the peculiar oblique connection and the special glue fixing treatment to the joint area can minimize the reduction of the tensile strength and ensure that the conveyor belt is still operating efficiently and lastingly.

High temperature resistance Generally, the surface temperature of the tile hot plate is 170-190°C. The higher the tile speed, the higher the surface temperature of the hot plate. The actual high temperature resistance of Ai Acupuncture Strip can reach 200°C, and Conveyor Traction Belt can adapt to dry heat, hot and humid environment. On both sides of the conveyor belt, it is easy to directly contact the hot plate due to the narrow corrugated web, which affects the service life. Therefore, we use Nomex fiber (resistant to 280°C) on the surface of the acupuncture belt. This fiber is a thermosetting material and will not melt, effectively extending the service life of the conveyor belt.

The running speed is one of the most important components of the tile line. The conveyor belt is driven by the double-sided machine driving roller, so Corrugated Paper Conveyor Belt must be able to fully synchronize with the operating speed of the tile line, otherwise it will cause poor adhesion of the corrugated cardboard. Reduced yields and other consequences. Ai Acupuncture with a unique structural pattern and excellent materials, not only fully consistent with the high-speed, high tensile force of the tile line running requirements, but does not run sideways, no slipping, so that the improvement of production and quality are achieved simultaneously.

In addition to rubber cleaning, we all know that whether the surface of the conveyor belt is clean or not is an important factor in ensuring the smooth running of tile lines and the quality of the cardboard surface. We apply a special silicone treatment to penetrate the surface of the acupuncture band, which not only ensures the friction and adhesion between the surface and the cardboard, but also removes the viscose on the surface without pulling out the fiber. It is easier to clean and can be soaked in water. It is suitable for soft brush cleaning, which makes it difficult to maintain the conveyor belt.

With the increasingly fierce competition in the market today, the profits of traditional industries will be even more meager. For the carton industry, improving quality and output, while reducing the waste of cardboard in production, is clearly the key to the survival and development of the company. As a leader in the industrial belt industry, we is willing to share the rich experience accumulated over the years and is willing to share it with the majority of carton enterprises.